Strip Feeder CNC AERN

Strip Feeder CNC AERN

Strip Feeder Numerical Control CNC AERN

The AERN CNC Strip Feeder is a key component for feeding strips of various formats to Eccentric Presses, Hydraulic Shears, etc. Unlike other models, this AERN features adjustable pneumatic cylinders to control the pressure on the material.

What advantages do we get with a CNC Roller Feeder compared to a Pneumatic Clamp Feeder?

- The feeder volume is more compact:

- A Pneumatic Feeder with a 300 mm advance will take up about 2 meters.

- This CNC roller feeder will take up 500 mm, resulting in a significant space-saving.

- Quick Change of Advance:

- In a pneumatic feeder, we need to adjust the spindle to limit the cylinder stroke to the required step.

- In the CNC roller feeder, the change of advance is done via the touch screen, simply by modifying the advance to be performed.

- Variable Step:

- The pneumatic feeder is designed to always perform the same step. If we set the advance for a 200 mm step, it must always perform the same step.

- It is possible to perform advances of different lengths, such as an advance of 50 mm, another of 100 mm, and another of 25 mm, and repeat this combination as many times as desired.

- Negative Step:

- The pneumatic feeder does not have the possibility of negative steps.

- The ability to perform steps in the reverse direction of the advance.

- Other advantages of the CNC Feeder over a pneumatic one with optional accessories:

- Programming the pieces to be produced.

- Work by pushing material or pulling material.

- Opening of the rollers for working with die centering devices.

- Speed regulation through the touch screen.

- Regulation of acceleration and deceleration ramps to adapt them to the weight of the material (inertia).

- Average production per minute.

INTRODUCTION

- Roller Feeder by Numerical Control for quick change of measures and steps of different lengths.

- Suitable for most strips such as HR, CR, Aluminum, Stainless Steel, Copper, PVC, etc.

- The Feeding Tolerance is (± 0.03 mm).

- Feeding length from 0.1 mm to 9,999.99 mm.

- Variable step programming (+100×3, +50×2, -25×1, …).

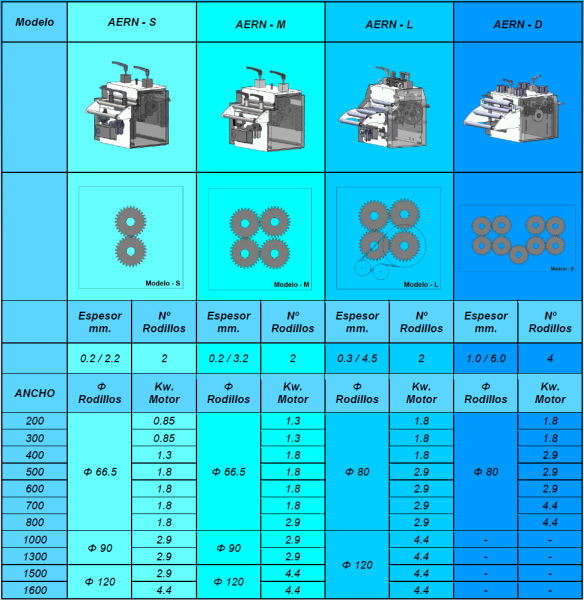

- Maximum Material Width from 200 mm to 1,600 mm.

- Thicknesses from 0.2 to 2.2, 3.2, 4.5, and 6 mm.

- Material clamping system for working with centring dies.

MECHANICAL CHARACTERISTICS

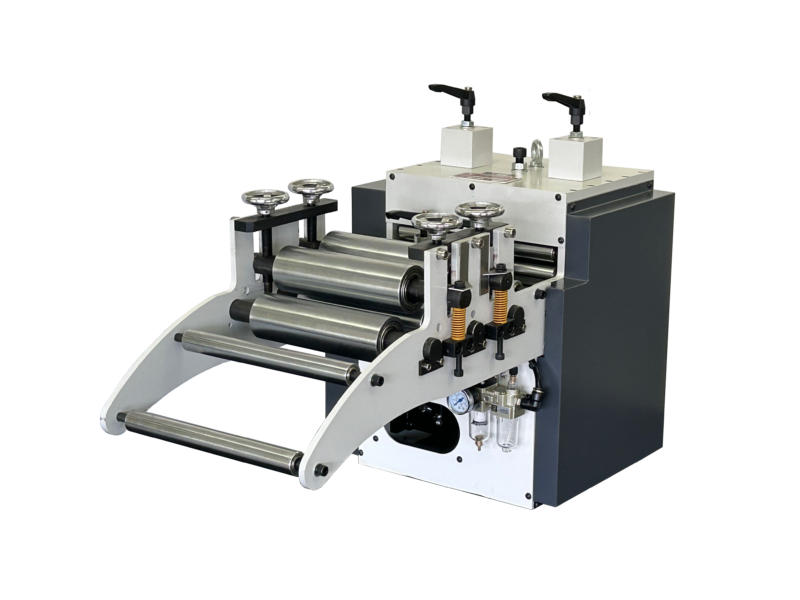

- The strip feed is driven by a Brushless motor.

- The Feed Rollers are high-hardness and anti-friction, made of thermally treated steel alloy with hard chrome plating and precision grinding. The hardness is up to HRC60.

- A Precision Gear Train synchronizes the upper and lower rollers.

- The transmission from the motor to the rollers is via a toothed belt, eliminating mechanical play.

- The upper roller is mounted on a pneumatically actuated cam for working with centring dies and facilitating material introduction.

- The pressure of the upper roller on the material is pneumatically adjustable to avoid strip lamination.

- Pressure compensation on the material is adjustable via springs.

- Height-adjustable Press Fixing Plate by 70 mm for alignment to the die.

- Lateral strip centering devices.

- Filtering and Regulation Unit for optimal pneumatic operation.

- Simple and robust construction for a long service life, easy installation, and maintenance.

AERN models can be combined with press lines, cutting lines, profiling machines, etc.

ELECTRONIC FEATURES

- Control and management of the system by PLC programmable control and Servo Control of the highly reliable and precise motor.

- High-resolution Touch control panel for entering work parameters.

- Adjustment of Advance Speed, Acceleration, Total Production.

- Alarm messages for quick identification of the Feeder’s status.

- Electric signal for start of advance.

- Electric signal for the unclamping device for working with matrix centers.

- Electric signal output to the press when the advance is complete, highly recommended for long advances, with the press step-by-step.

- Remote control to operate from the press.

- Mobile electrical cabinet with wheels, up to 3 meters from the feeder.

- All electrical components are from top brands: Siemens, Yaskawa, Mitsubishi, Schneider, etc.

At the customer’s request, SEGURA LLUNELL, S.A. specializes in the study, design, development, and complete assembly of Automatic lines.

We can equip the CNC Feeder with Press, Decoiler, Straightener, Lubrication rollers for the strip.

Thanks to our partners in Tooling, we can deliver a turnkey project. The customer receives the entire line working in our workshops in Polinya-Barcelona, producing the desired part.

Technical Features

*Section in mm/square: If the width of the material is reduced, the thickness can be increased. Request.

STRAIGHTENER FOR CNC FEEDER AERN

FEEDER WITH STRAIGHTENER

The AERN Feeder has the possibility of attaching a non-motorized straightener.

This straightener can facilitate the straightening of the material due to the curvature that comes from the roll of the decoiler; the maximum thickness to be straightened will be half of the maximum thickness of the Feeder and will depend on the width and hardness of the material.

ADJUSTABLE STAND FOR CNC FEEDER AERN

ADJUSTABLE STAND

For quick and convenient height adjustment of the feeder, when we have dies of different heights.

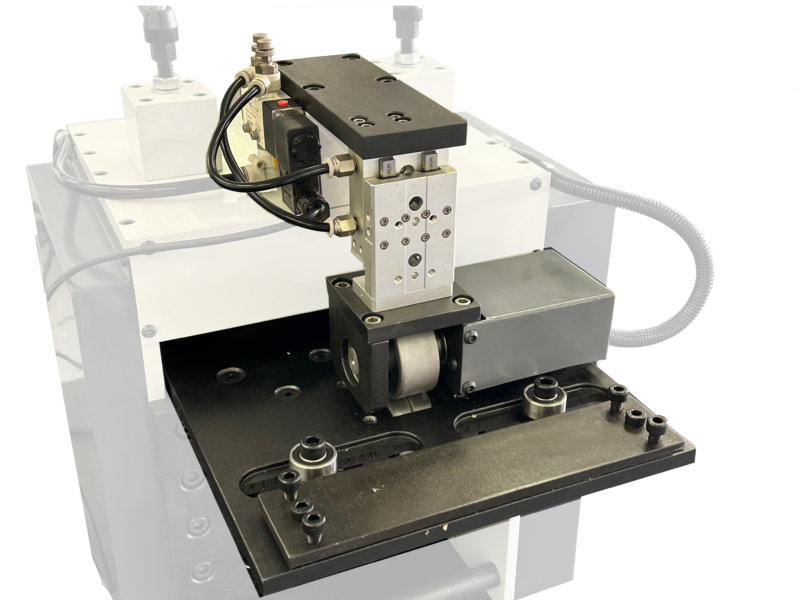

EXTERNAL ENCODER FOR CNC FEEDER AERN

EXTERNAL ENCODER

The AERN Feeder has the possibility of mounting a second encoder.

This external encoder verifies the amount of millimeters fed by the main motor and, if necessary, performs the automatic correction.

Recommended for lengths of more than 1,000 mm, irregular materials, and complex dies where the strip does not have guarantees of advancing freely.