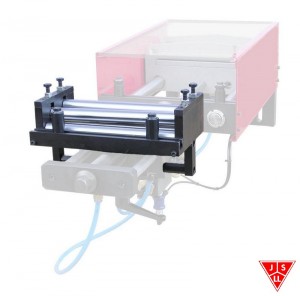

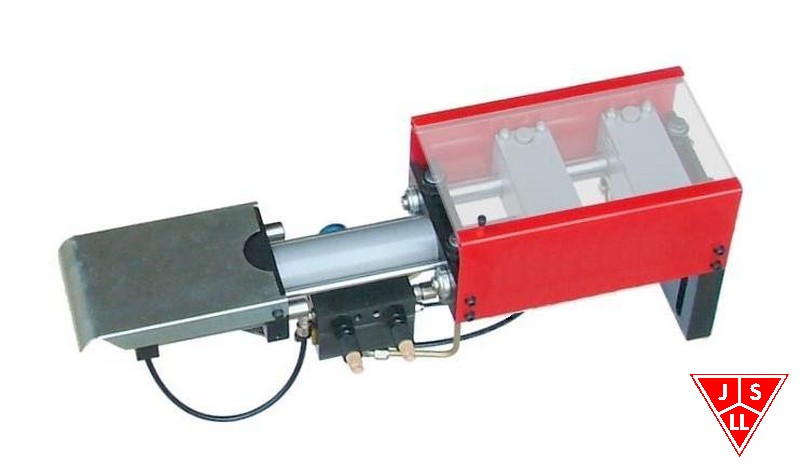

Pnemuatic Feeder AN 10 for Coil

Pnemuatic Feeder AN 10 for Coil

Pnemuatic Feeder AN 10 for Coil

- This Pnemuatic Feeder AN 10 is constructed of high quality tempered sheet steel and aluminum.

- The feeder is supplied with an end-of-feed damper.

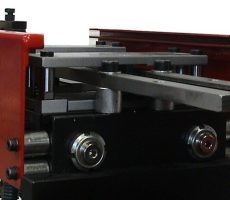

- Jaws actuated by means of several independent pneumatic cylinders, to ensure a perfect clamping in cases of material burr.

- Two side covers and one upper one, made of sliding methacrylate or sliding metal to protect the jaws.

- Sistema de seguridad de avance despues del amordazamiento del material.

- Advance safety system after clamping of the material.

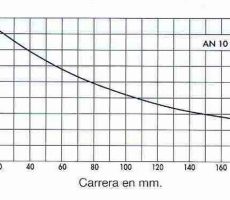

- Regulation of the Advance Stroke by means of a spindle with millimeter rule.

- The advance of the material is guaranteed by means of a series of pneumatic valves, with which the following work phases are obtained.

- Locking the mobile jaw and opening the fixed jaw

- Advance of the mobile jaw..

- Locking of the fixed jaw and opening of the mobile.

- Return of the mobile jaw.

- This Pneumatic Press Feeder is constructed of high quality tempered sheet steel and aluminum.

- The feeder is supplied with an end-of-feed damper.

- Jaws actuated by means of several independent pneumatic cylinders, to ensure a perfect clamping in cases of material burr.

- Two side covers and one upper one, made of sliding methacrylate or sliding metal to protect the jaws.

- Sistema de seguridad de avance despues del amordazamiento del material.

- Advance safety system after clamping of the material.

- Regulation of the Advance Stroke by means of a spindle with millimeter rule.

- The advance of the material is guaranteed by means of a series of pneumatic valves, with which the following work phases are obtained.

- Locking the mobile jaw and opening the fixed jaw

- Advance of the mobile jaw..

- Locking of the fixed jaw and opening of the mobile.

- Return of the mobile jaw.

| Model | Strip Width mm. | Strip Advance mm. | Strip Thickness mm. | Nº Cylinders Fix and Mobil Jaw | Power Mobil Jaw Kgs. | Power Fix Jaw Kgs. | Push Power kgs. | Air Consumption Liters (A) |

| AN 10.6 | 3/100 | 3/60 | 0’2/1 | 2+2 | 136 | 136 | 75 | M=0’03 C1=0’17 |

| AN 10.10 | 3/100 | |||||||

| AN 10.15 | 3/150 | |||||||

| AN 10.20 | 3/200 |

| Accesorio | Descripcion |

| Unidad de Filtraje | Perfecta Lubricacion de todas las partes del Alimentador |

| Equipo de Sincronizacion | Para prensas mas rapidas que el Alimentador |

| Dispositivo Autocentrante | Funcion de apertura del alimentador con matrices con centradores |

| Dispositivo Trabajo en Tiro | Permite al alimentador trabajar tirando del material |

| Dispositivo Trabajo Tiro/Empuje | Permite al alimentador trabajar tirando del material o empujando |

| Mando Alimentador por EV. | Inicio del avance por Electrovalvula |

| Mando Autocentrante por EV. | Accionamiento de Autocentrante por Electrovalvula |

| Camisas Proteccion Mordazas | Camisas de Material Plastico para materiales extramadamente delicados |

Related Products